Superconductivity offers zero to near zero resistance to the flow of electrical

current when cooled below a particular cryogenic temperature, and additionally,

superconducting materials are able to carry much larger current densities than

conventional materials, such as copper. In rotating machines, increasing the current and/or magnetic flux density increases the power density, which leads to

reductions in both size and weight of the machine. The expected improved performance and efficiency, as well as smaller footprint, has seen continued interest in

using superconducting materials in rotating machine designs. In this preface, we

introduce some of the recent advances in superconducting rotating machines and

their related technologies that form this special issue.

Over several decades of research, various superconducting machines have

been shown to be technically feasible over a wide range of power ranges, for

applications in electricity generation (conventional, hydroelectric, and wind turbines) and motors for ship and aircraft propulsion and electric vehicles. For the

first such attempts—synchronous generators using low temperature superconducting (LTS) materials—the complexity and cost of 4 K cryogenics hindered

the commercial development of these machines , although there were a number

of successful technical feasibility demonstrations . The discovery of high

temperature superconducting (HTS) materials renewed enthusiasm for applied

superconductivity research with the expectation that these materials could be

exploited at 77 K, the boiling point of liquid nitrogen. Since then, a number of

projects around the world have demonstrated the technical feasibility of HTS

machines in various forms. Many of these demonstrators have been based on the

first generation HTS conductors (BSCCO) ; however, the focus has recently

shifted towards the second generation (2G) HTS conductors ((RE)BCO, where

(RE) is a rare earth element or yttrium), which exhibit comparatively better

superconducting properties.

In , Moon et al report the design, fabrication and preliminary tests of a

megawatt-class 2G HTS motor, designed specifically for ship propulsion, at

Doosan Heavy Industries and Construction. The rotor consists of racetrack coils

wound using GdBCO wire, which is cooled by forced circulation of liquid neon to

achieve an operating temperature less than 30 K. The preliminary tests showed

measured values consistent with the design specification, but a number of technical issues, such as coil impregnation, improving mechanical strength and

reducing the necessary cooling time, are raised as future considerations.

The stator in this case is based on conventional technology, and until now,

many other designs have focused chiefly on this kind of design: an isolated,

cryogenic rotor and conventional stator, or in other words, a hybrid superconducting machine based on conventional synchronous machine design.

However, a conductor with low AC losses would allow for the use of HTS

conductors in both the stator and rotor windings, leading to the development of an

all-cryogenic or all-superconducting machine with unprecedented power densities.

In, Song et al provide a comprehensive analysis of the thermal behaviour of an

HTS stator employing BSCCO windings on an iron core, cooled to 82.1 K by

liquid nitrogen, and a permanent magnet (PM) rotor.

Another technical challenge for superconducting rotating machines with a

rotating DC field winding is the need for brushes/slip-rings as a rotating joint. In , Bumby et al demonstrate a prototype brushless HTS-PM exciter to avoid this

problem, making use of a flux pump to inject current into a closed HTS coil

without the need for a direct electrical connection to the rotor, which additionally

removes thermal penalties associated with current leads. The exciter can also

operate externally across a cryostat wall without forming a thermal bridge.

In order to avoid rotating magnets/coils and AC losses, Fuger et al have

developed superconducting homopolar machines, which utilise only DC electric

and magnetic fields for operation. The operating principle and design of such

machines is presented in , including the first experimental results from a

200 kW motor demonstrator. Liquid metal current collectors deliver a low

resistance, stable and low maintenance sliding contact to the rotor. In ,

Radyjowski et al report on an initial prototype claw-pole superconducting

machine that has a modular design, as well as a stationary superconducting field

winding, eliminating the need for cryocouplers, brushes and so on. Campbell

analyses the possibility and performance of a superconducting magnetic gear

using HTS conductors in , which could replace a conventional gearbox in an

electric machine and offer reduced acoustic noise and vibration, as well as

improved reliability and significantly reduced maintenance.

There is great interest in the application of superconducting machines in direct

drive wind turbines for wind power generation, particularly for the offshore

market, which demands reliable, lightweight and high power density solutions.

Additionally, there is considerable interest in applications of MgB2 superconducting materials as an alternative to LTS and HTS materials, offering a

number of advantages as low cost and density conductor with potentially low AC

losses. In , Marino et al report the design of a 10 MW, 8.1 rpm superconducting generator for direct drive, offshore wind turbines that uses MgB2 field

coils cooled to 20 K and a conventional, ambient temperature stator winding. A

weight reduction of 26% in comparison to a conventional PM generator is estimated, which would allow a tower 11% lighter. As part of the same SUPRAPOWER project, Vargas-Llanos et al use finite element analysis in to estimate

the hysteretic losses in multi-filamentary MgB2 tapes under the operating conditions of the SUPRAPOWER prototype generator, including an AC transport

current and a DC transport current under an external applied magnetic field, with

and without ripples from the coupling between the stator and rotor. The influence

of filament transpositions within the tapes on the AC loss is also examined.

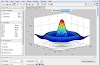

Bulk superconducting materials, which acting as trapped field magnets can

trap magnetic fields of magnitude over ten times that of conventional PMs ,

also have the potential to act as PM analogues in superconducting rotating

machines. The TUMSAT group in Japan has worked on axial gap-type superconducting rotating machines employing bulk HTS materials for over a decade

and provides an overview of their developments to date, including bulk

material fabrication, pulsed field magnetisation and experimental test results on a

number of prototype machines. Finally, the design and build of a fully superconducting magnetic bearing system using bulk YBCO and Nd-Fe-B PMs is

reported by Xu et al in . This has potential application in high speed rotating

machines as a superior, friction-free bearing with low loss and noise.

0 Comments