ESSENTIAL

QUALITIES OF HV CIRCUIT BREAKER

High-voltage circuit breaker

play an important role in transmission and distribution systems. They must

clear faults and isolate faulted sections rapidly and reliably. In-short they

must possess the following qualities.

" In closed position they

are good conductors.

" In open position they

are excellent insulators.

" They can close a shorted

circuit quickly and safely without unacceptable contact erosion.

" They can interrupt a

rated short-circuit current or lower current quickly without generating an

abnormal voltage.

The only physical mechanism

that can change in a short period of time from a conducting to insulating state

at a certain voltage is the arc.

HISTORY

The first circuit breaker was

developed by J.N. Kelman in 1901. It was the predecessor of the oil circuit

breaker and capable of interrupting a short circuit current of 200 to 300

Ampere in a 40KV system. The circuit breaker was made up of two wooden barrels

containing a mixture of oil and water in which the contacts were immersed.

Since then the circuit breaker design has undergone a remarkable development.

Now a days one pole of circuit breaker is capable of interrupting 63 KA in a

550 KV network with SF6 gas as the arc quenching medium.

THE NEED FOR

TESTING

Almost all people have

experienced the effects of protective devices operating properly. When an overload

or a short circuit occurs in the home, the usual result is a blown fuse or a

tripped circuit breaker. Fortunately few have the misfortune to see the results

of a defective device, which may include burned wiring, fires, explosions, and

electrical shock.

It is often assumed that the

fuses and circuit breakers in the home or industry are infallible, and will

operate safely when called upon to do so ten, twenty, or more years after their

installation. In the case of fuses, this may be a safe assumption, because a

defective fuse usually blows too quickly, causing premature opening of the

circuit, and forcing replacement of the faulty component. Circuit breakers,

however, are mechanical devices, which are subject to deterioration due to

wear, corrosion and environmental contamination, any of which could cause the

device to remain closed during a fault condition. At the very least, the

specified time delay may have shifted so much that proper protection is no

longer afforded to devices on the circuit, or improper coordination causes a

main circuit breaker or fuse to open in an inconvenient location.

TESTING OF

CIRCUIT BREAKERS

The design of circuit breaker

is not only a science but also an art. Because of the complex phenomena

involved, circuit breaker prototypes have to be verified by practical tests in

the laboratory. There are two types tests of circuit breakers, namely Routine

tests and Type tests. Routine test are performed on every piece of circuit

breaker in the premises of the manufacturer. The purpose of the routine test is

to confirm the proper functioning of a circuit breaker. Type tests are

performed in a high voltage laboratory; such tests are performed on sample

pieces of circuit breaker of each type to confirm their characteristics and

rated capacities according to their design. These tests are not performed on

every piece of the circuit breaker. All routine and type tests are performed

according to Indian Standard (IS) codes, or International Electromechanical

Commission (IEC) codes or British Standard (BS) codes.

In High-power laboratories the

ability of the circuit breakers to interrupt the circuit currents is verified

in test circuits which is infact the lumped element representation of the power

system. These test circuits must produce the corrected forms of the short

circuit current as well as the final voltage that strikes the circuit breaker

immediately after the breaker has interrupted the test current. The forms of

voltage and current to which the test object must be subjected are laid down in

ANSI and International Electromechanical commission (IEC) standards. These

standardized waveform represent 90% of the possible conditions in the real

system.

CIRCUIT

BREAKER SWITCHING AND ARC MODELLING

The switching action, the basic

function of the circuit breaker refers to the change from conductor to

insulator at a certain voltage. Before interruption, the short circuit flows

through the circuit breaker arc channel. Because of non zero resistance of the

channel , the short circuit current causes a voltage across the contacts of the

circuit breaker; the arc voltage. The arc behaves as a non-linear resistance.

Thus both are voltage and arc current cross the zero value at the same time

instant. If the arc is cooled at the time current goes through zero the circuit

breaker interrupts the current because the electrical power input is zero.

During current interruption, the arc resistance increases practically from zero

to almost infinity in microseconds. Immediately after current interruption, the

transient recovery voltage builds up across the circuit breaker .As the gas

mixture in the interelectrode space does not change to a completely insulating

state instantaneously, the arc resistance is finite at that time and a small

current can flow ;the post –arc current.

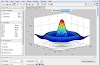

Black box arc models are

mathematical description of the electrical properties of the arc .This type of

model does not simulate the complicated physical processes inside the circuit

breaker but describes the electrical properties of the circuit breaker.

Measured voltage and current traces are used to extract the parameters for the

differential equations describing the nonlinear resistance of the electrical

arc for that specific measurement.

0 Comments