Induction motors (IMs) have a number of advantages in general industrial applications, including robustness, better reliability, fewer maintenance requirements, smaller volume, and cost. Because of these, induction motors are more widely used than DC motors. However, the mathematical model of an IM consists of a set of nonlinear time-varying high-order differential equations, which makes the control of an IM drive much harder than that of a DC drive and requires complicated control methods. Through suitable coordinate transformations, the field orientation control method enables an IM drive to achieve comparable DC drive performance, thus resulting in extensive utilization in high performance industrial drive applications .

The field orientation control approaches of IM drives can in general be classified into three modes of flux-based control: rotor flux, stator flux, and air-gap flux . In the rotor-flux mode approach, rotor flux and stator current are chosen as control state variables; in the stator-flux mode, stator flux and stator current are the control state variables; while in the air-gap-flux mode, air-gap flux and stator current are the control state variables. Furthermore, the field orientation control of IM drives can also be classified into indirect or direct vector control categories. In the indirect vector control approach, the flux position can be calculated from the rotor-shaft angular position and the estimated slip angle, while in the direct vector control approach, the magnitude and angle of the flux can be directly estimated based on the measured motor currents and voltages .

Fuzzy control design

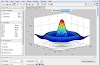

The design of the fuzzy logic controller is proceeded by applying the linguistic imprecise knowledge of human experts and the behavioral nature of the plant. Comparing to the design of conventional PI controllers, no precise mathematical modeling information of the plant is required . The principle of fuzzy logic control, according to the linguistic rule, utilizes fuzzy inference to transform definite quantification input signals into fuzzy output signals. These signals are then converted to definite quantity to govern the plant . The fuzzy logic controller is composed of fuzzification, fuzzy knowledge base, fuzzy inference, and defuzzification.

Fuzzification

Fuzzification, according to fuzzy set theory, converts crisp input values into corresponding fuzzy values. The numbers of fuzzy sets determine the computation speed of the fuzzy logic controller. In this paper, the fuzzy set is defined as Negative Large (NL), Negative Small (NS), Zero Error (ZE), Positive Small (PS), and Positive Large (PL).

Fuzzy inference

The output feature is decided by the fuzzy rule but the output measure is dependent on the fuzzy inference. The Min–Min–Max method is applied to dominate the fuzzy inference. The first Min term is regarded as fuzzification step, which uses minimum trigger as the membership grade. The second Min term is regarded as output membership grade for each fuzzy inference rule, i.e. taking the minimum value between two input membership grades according to the fuzzy inference rules. The third Max term is regarded as integrating the same output membership functions into individually rule, i.e. taking the maximum value.

Fuzzy rule

The fuzzy rule is composed of the linguistic term if-then, for which the output membership function requiring to be trigged is decided by the fuzzy rule, i.e., it defines the relation between the output and the input. For example, the relations between the input variables,

and

, and the output variable

are defined as

Defuzzification

Defuzzification converts the inferred fuzzy output value into the crisp output value and then utilizes the crisp output value to govern the plant. At this stage, the center of sum defuzzification is used, which defined as

where

is the height of each

and

is the most center value of

before the top of

is cut off.

Conclusions

A fuzzy logic speed sensorless control strategy based on the current-and-voltage parallel-model stator-flux estimator has been proposed to control an IM drive. The proposed estimator can estimate the rotor shaft speed on-line for different speed regulation commands and both simulation and experimental results have confirmed that the fuzzy logic control scheme can acquire superior speed control responses under loading conditions. All control algorithms are executed on a DSP 6713 and drive the motor, using a DSP F2812 to generate PWM signals to the power-module stage of an inverter. The simulated and experimental responses at three speed different reversible speed commands (±1800, ±900, and ±300 rpm) confirm the effectiveness of the proposed approach.

0 Comments